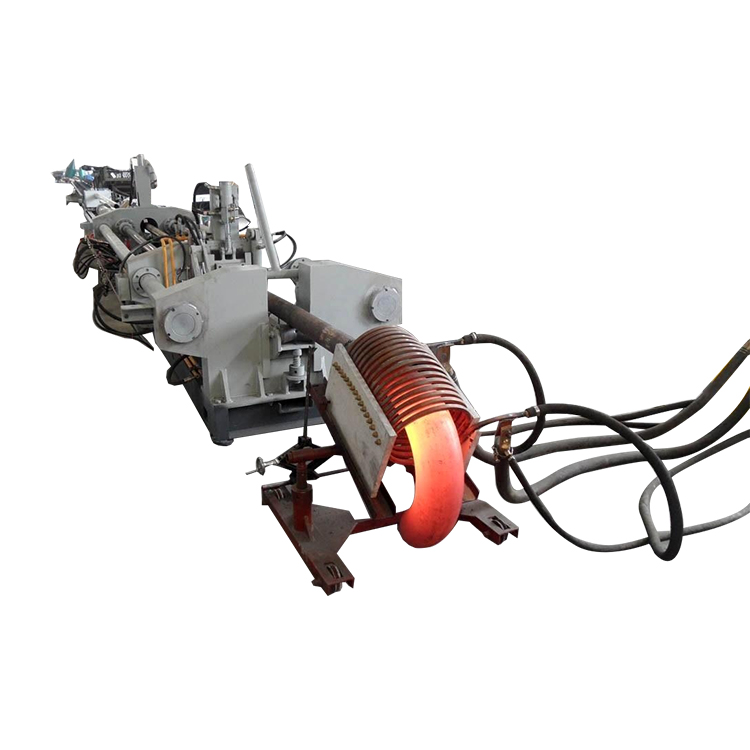

| Bend machine manufacturing technology forming

Elbow machine is the main equipment for producing elbow pipe fittings. The design of the elbow head and the bed stiffener eliminates the internal stress by annealing. The whole elbow pipe has enough lightness and stiffness without deformation. Before making elbow fittings, the elbow machine must first be accurately installed and maintained, the production process runs smoothly, the overall processing, the overall hobbing, and the elbow wall thickness is customized according to customer needs. The material used is steel plate.

Elbow pipe fittings produced by elbow machine are widely used in pipelines of petroleum, chemical, textile, electrical and other modern industries. The forming methods mainly include extrusion, extrusion stamping, pushing and thermoforming. Among them, extrusion, extrusion stamping and pushing molding at room temperature are commonly used methods in pipeline fittings factories, but each has its own characteristics.

According to the theory that the wall thickness of the hot push elbow is not thinned, combined with the process characteristics and difficulties of the medium frequency induction heating push of small and medium-sized stainless steel seamless elbow, the heat strength problem of the mandrel is solved by designing a suitable hollow mandrel and using the inner hole of the mandrel to cool the inner wall of the mandrel in a lower temperature area.

Before using the elbow machine, the following needs to be tested: First, fix the mandrel with the clamping die of the elbow machine, and put the clamping die of the elbow machine into the fixing mandrel with the clamping die. The positive screw for adjusting the base of the steamed bun is to seal the steamed bun in the wheel mold. When installing the back clamping button, move the steamed bun back, turn the clamping die clockwise, and adjust the screw balance 1/2-1/4. It is mainly the nut that holds the fixture.

The manufacturing technical requirements of the elbow machine are manufactured and formed according to customer requirements. In the manufacturing process, the engineers of our company first produced a drawing for the customer, and after obtaining the recognition of customer satisfaction, our company provided the processing and molding for the customer. The processing principle of the elbow machine: the core head with a certain geometric shape and size is the mold, that is, the angular core head, and the core rod with the appropriate length is welded at the back. The length of the core rod is determined by the length, size and quantity of the tube blank pushed back and forth in each operation. Before pushing, the tube blank to be pushed through the end of the core rod into the core rod, and then sent to the push plate. When pushed, the push plate begins to push the blank forward.

The elbow machine can push the elbow pipe from different angles, and the elbow machine can produce the same elbow of various materials according to the needs of customers. Elbow machine in the production process of simple operation, advanced production efficiency. Elbow machine is divided into active operation and manual operation. Elbow machine manufacturers can be manufactured according to customer needs.

Elbow manufacturing process: Send the formed elbow into the correction mold of the hydraulic press table with a forklift to complete a bend correction, and remove the reduced diameter corrected elbow from the correction mold with a forklift. Then roughing, using machine processing or gas to cut off the excess elbow at both ends, reserving 10 to 15 mm groove processing allowance. The elbow machine is used for the composition of the elbow, the main power is a hydraulic cylinder, and the heating method is medium frequency heating (except coal furnace and gas heating). The bending machine has the advantages of high geometric accuracy, uniform wall thickness, stable structure size, good mechanical performance and high productivity.

Function of elbow machine: The main function is to produce complete models of elbow pipe fittings, can be mass production and processing elbow pipe fittings. Elbow machine can meet the quality requirements of elbow pipe fittings. For the development efficiency in recent years, the elbow machine has brought effective benefits to customers who produce elbow pipe fittings! The advantage of producing elbow fittings is that it can produce elbow fittings with a wall thickness of 21-1620 mm and above 3-120 mm, and can produce elbow fittings ordered by customers at one time. Elbow machine production and processing materials are divided into carbon steel, alloy steel and stainless steel. The elbow machines we produce can be processed. The elbow pipe fittings produced by the elbow machine are beautiful in appearance.

The transmission spindle of the bending machine produced by our company is directly inserted into the upper part of the machine head, accurate installation and easy maintenance. The elbow spindle and drive sprocket are driven by two cylinders and are driven by integral casting, integral machining, integral rolling teeth, keyless connection and average force. In the elbow process, the hydraulic system automatically throttling buffer before the boom approaches the bending set Angle, greatly improving the bending accuracy, fast reset, throttling buffer close to the beginning, greatly improving the reset accuracy and work efficiency.

For more information about the elbow machine, please pay attention to our website: http://www.aocjx.com

|